Originally developed in Europe, Aluminium Composite Panel (ACP) are gaining popularity beyond the Middle East. With the rise of construction work in the UAE, this has triggered interest in India too for various external and internal applications.

What is aluminium composite panel?

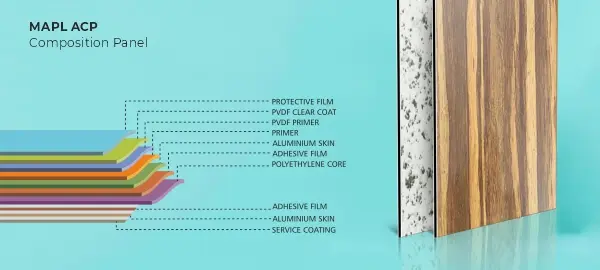

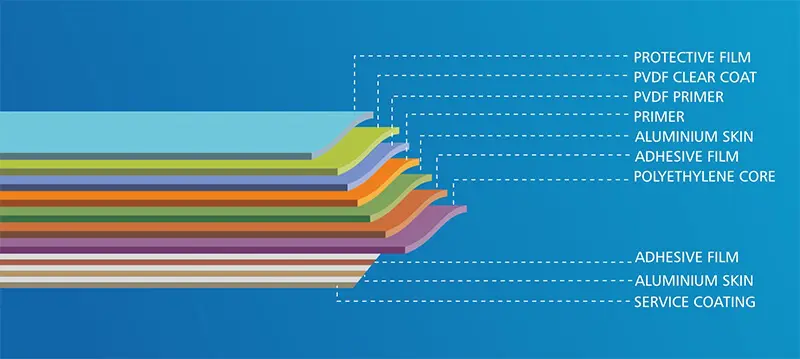

ACPs are also called Sandwich Panels. They have an Aluminium Composite sheet that has a polyethylene core. The ACP is made of three layers: a core that has low density, and a thin layer bonded from each side. The ACPs are used in application areas where there is a need for high structural rigidity and yet it has to be low in weight. Let’s see further as to why the ACPs are gaining popularity.

Characteristics of Aluminium Composite Panel(ACP Sheets)

The ACPs are a blend of polyethylene and polypropylene plastics that are bonded so well in the manufacturing process that once processed it is very difficult to separate the aluminium composite panel sheets.

• Durability: Since the ACPs are coated with Fluorocarbon they are resistant to dust, weather, high temperature, wear and tear and pollution making them extremely durable.

• Light weight: The structural rigidity matches with the light weight of the ACPs making them much favourable for use in construction. Due to its light weight it is also faster to install thereby accelerating the construction process.

• Fire Resistance: The outer foil of aluminium helps prevent the core inside from heat conduction during the initial combustion process. This characteristic meets international standards of safety.

• Customization: The ACPs can be customized according to the size, shape and design or pattern requirements. This helps customers to be more able to adapt their environment and change it as per the suitability of their needs. Bendable feature makes ACPs an all time favourite for construction work.

• Design and Color: Any kind of design or color can be had for the ACPs making them attractive also. They can blend well with the environment and even enhance its appearance due to their metallic finishes and patterns.

Types of Aluminum Composite Panel

To look into the application areas and various ways in which the ACPs can be used, let’s check the different types of ACPs. ACPs are of different types depending on the finishings given to them:

• matte finish that gives a rough touch

• plain finish that just blends with the environment

• wooden finish plays well with the natural look

• Stone finish provides a shine that outshines

• marble finish gives a durable and lasting impression

These panels are used for different requirements and hence they differ in sizes too.

Uses of Aluminium Composite Panel

The aluminium composite panel uses have expanded over the years. Earlier they were thought of to be used for just partitioning. Now, they have an extensive range of applications internally and externally due to their inherent characteristics. Sometimes they are used along with other materials like glass in the building.

Since the ACPs can be cut, fit, bent, drilled or perforated without it losing its structure, they are widely used for external claddings, building facades, insulation areas and signage.

With a wide range of application areas, totally amazing characteristics and features, beautiful range of design and colours, the ACPs are a boon for the construction industry, interior designers and for building artworks. They way forward for the ACP is believed to be more possible due to scientific breakthroughs in construction technology that is achieving great strides everyday.

At MAPL, we believe in the blending of design, technology, usage and customer requirements to make the best products that promise more ease of living.